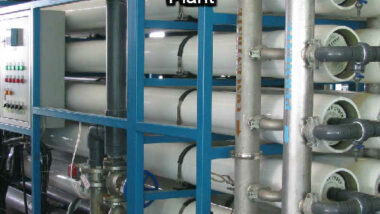

The Reverse Osmosis process is unique, it alone consistently removes salts (salinity) from leachate, apart from prohibitively energy expensive, physical evaporative methods, so it is an obvious candidate for leachate treatment where the regulatory body requires water to be discharged which is largely free of saline content, and is therefore suitable for irrigation without the risk of salinity build-up in soils, and water bodies.

The Reverse Osmosis process is unique, it alone consistently removes salts (salinity) from leachate, apart from prohibitively energy expensive, physical evaporative methods, so it is an obvious candidate for leachate treatment where the regulatory body requires water to be discharged which is largely free of saline content, and is therefore suitable for irrigation without the risk of salinity build-up in soils, and water bodies.

However, the RO process is no more than a filter which has pores so small that they provide filtration at the molecular level. Inevitably, the contaminants in leachate including Sodium Chloride, (which are held on the filter surface when the clean water passes through) cannot be left to build-up, so they are washed off and become part of the “concentrate” which must be disposed of in some way. Off-site disposal of the concentrate to an incinerator licensed to accept hazardous liquid wastes is an obvious method of disposal and yet it is normally prohibitively expensive to do this. RO systems generally produce about a quarter of the inflow as concentrate and the remainder as permeate, so the cost of this would, in fact, be very high indeed and on-site treatment would be rendered more expensive than tanker disposal to a suitable treatment facility.

To be viable, Reverse Osmosis treatment facilities need to return the concentrate back into the waste from which it came.

That immediately raises a red flag in the minds of landfill designers who appreciate that no matter how good though their containment designs might be, they will not hold back the contaminants in the landfill forever, and some suggest that landfill cappings and linings are not likely to remain leak free for more than 100 years or so. Putting the contaminants back, even if partially biologically treated in an biological aeration treatment MBR before the flow enters the RO plants helps, seems to contravene all ideas of flushing the landfill clean. Ultimately, all salinity above the natural background salinity needs to be flushed out of all landfills before they will become fully safe to the environment.

Recirculation of RO concentrate will always return the salinity back into the waste. That salinity is negligibly reactive within the waste, say many landfill experts, so why won’t it just build-up in the landfill and eventually be seen at the RO plant intake as a progressive increase in salinity in the leachate which has to be treated? If leachate salinity rises, the RO Plant itself will suffer. That is due to the fact that as salinity increases in the raw leachate a progressively higher water pressure will be needed to achieve the same flow needed through the RO Plant. This raising of the osmotic pressure is generally possible to do, but there is a penalty in doing so, as the energy consumed by the RO process then also rises in order to continue to achieve the same flow.

So, the question whether the salinity, and other important parameters for increased fouling of membranes such as iron, have been found in real-life to rise, is an all-important one. Intuition might suggest that the salinity would rise as the salt content is unlikely to react with the waste and would be expected to stay in solution and run right through and out of the landfill in the leachate, but does it?

To answer this question it would be necessary to do a full and up to date review of all papers written on this subject. However, for the remainder of this article I will provide details and comment on the interesting conclusions in just one such paper on the subject of the sustainability of RO concentrate recirculation, as follows.

The information which follows is based upon a paper titled: “Recirculation Of Leachate Concentrate From Reverse Osmosis Treatment”, by P.L.A. Henigin, of WAT, Kleinoberfeld 5, 76135 Karlsruhe, Germany. The paper is published in the Proceedings of the Fifth International Landfill Symposium, “Sardinia 95”, held at S. Margherita di Pula, Cagliari, Italy; 2-6 October 1995.

“SUMMARY: The effect of the concentrate return after the membrane-filtration on the new formation of leachate was investigated in a long-term simulation. The results show no significant difference of leachate quality with or without return of concentrates.

1. INTRODUCTION

The concentrate of the membrane-filtration has been returned to the landfills for several years at some German sites for MSW. The pertinent results show that no harmfull concentration of toxic substances is expected (Henigin, 1993). To verify these results, a long-term simulation was performed at the landfill site “Deponie Kapiteltal” of the “Deponiezweckverband Kaiserslautern”, Germany, from June 1993 to February 1995.”

Experimental set-up: Waste packed cylinders were set up so that the formation of leachate could be simulated under varying precipitation conditions and additional concentrate return. Since, with time the waste in the landfill undergoes a metamorphism which is caused by biochemical degradation processes, two parallel pipes were set up. These were filled with the same type of waste. In addition to the simulated precipitation, the concentrate taken from a reverse osmosis plant was put into one of the pipes.

“2. EXPERIMENTAL SET-UP

2.1 Pipe Design

Both experimental pipes [vertical percolation cylinders] are shown in Fig.l. [not included here] Their total height amounts to 3.3 m, the outer diameter to 0.5 m and the inner cross-section area to 0,184 m2. The pipes are made of acrylic glass to enable eye-contact to the pipe contents during the experiment.4. DISCUSSION OF THE RESULTS AND CONCLUSIONS

The long-term simulation at the landfill site in Kaiserslautern shows that the leachate quality of the two pipes [vertical percolation cylinders], which were filled with waste, is not significantly changed when concentrate is added to one of them. A multitude of complex biochemical and physical processes that occure in the pipe and in the landfill, respectively, are responsible for this result. The main subprocesses are:

- Biochemical degradation processes which take place inside the landfill reduce the organic load of the landfill contents and of the concentrate as well

- Organic and inorganic deposits which consist of oxides, sulphides and carbonates are formed by microorganism (Bacterogenese) (Ramke et al., 1990)

- Heavy metals are fixed by adsorption processes on the surface of the landfill contents

- Crystallization processes cause the fixation of salts

- Inorganic chemical processes cause the fixation of carbonates, sulphides and sulphates (Schneider, 1993)

The interaction of these subprocesses ought to be the reason that the contaminants only reach a so-to-speak stable concentration in the landfill leachate. Significant divergences would only be expected as a consequence of extreme conditions. These include e.g. short circuits of the percolation ways inside the landfill (low concentrations) or the percolation of areas with specific industrial or commercial waste (high concentrations).

In conclusion, it remains to be stated that according to the performed long-term simulation at the landfill “Kapiteltal” of the “Deponiezweckverband Kaiserslautern”, the return of concentrate after reverse osmosis can be regarded as an appropriate step in leachate treatment.

5. REFERENCES

HENIGIN, P.LA. (1993) “Effects of the return of membrane-filtration concentrates on the new formation of leachate”. Procedings SARDINIA ’93 Fourth International Landfill Symposium, Vol. 1, CISA-Environmental Sanitary Engineering Centre, Cagliari

RAMKE, H -G. and BRUNE, M. (1990) “Untersuchungen zur Funktionsfahigkeit von Entwasse-rungsschichten in Deponiebasisabdichtungssystemen” Forschungsbericht 14504573, Umweltbundes-amt Berlin

SCHNEIDER, P. (1993) “Mineralogische Untersuchungen an Inkrustationen aus Deponieentwasse-rungssystemen”. Diplomarbeit an der Universitat Karlsruhe, Institut fur Mineralogie, Karlsruhe”

The all-important point in this extract comes in item 4 of the list of the chemical and biological subprocesses which take place in the leachate inside the landfill. Here we read that: “Crystallization processes cause the fixation of salts”, so there is a mechanism which has been put forward which could make a case for the recirculation of RO concentrate back to the landfill as being sustainable, as long as the crystalized salts will always remain in this non-soluble state.

Clearly, this is only one paper, and the results of further experiments are needed before the assertion that “crystalization” (item 4 on the list above) can be fully verified. Any reader of this article that possess further information, especially for example from later papers on this subject, is invited to contact us, so that we can review and comment on such texts.