time

How to Treat Landfill Leachate Using a Saltworks Crystallizer System

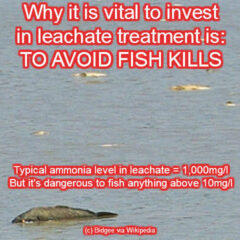

Until now, the search for the perfect Leachate Treatment System has remained a dull one for those that know leachate. Somehow, all those contaminants it contains have contrived to make the most commonly used solutions highly complex, dependent on advanced technologies, and hard to operate successfully. Read about the new technology in the SaltMaker Evaporator Crystallizer, for something completely new!

How Do You Treat Leachate?

First of all when asked the question, “How Do You Treat Leachate?”, we would like to make a distinction between true treatment which involves converting environmentally damaging substances to less, or non-toxic, ones, and simply concentrating the contaminants from the water in leachate to give a volume reduction. In the water industry both are known as […]

Anaerobic Digestion of Landfill Leachate for Energy Generation: Pipe-Dream or an Opportunity?

Anaerobic digestion is becoming increasingly popular in this age of high energy prices, and many more people are realising that whereas aerobic treatment systems consume large amounts of expensive energy, anaerobic digestion is a process which does the opposite. In fact it produces a net energy output. It is not surprising therefore, that many […]

Free Trade Effluent Charges Calculator Download

Download our FREE time saving calculator which is intended for use for trade effluent discharge cost assessments for England, Wales and Northern Ireland in respect of sewer discharges. The Free Trade Effluent Charges Calculator software will be useful for anyone making an industrial effluent discharge to a sewer, and who wants to know how much it will cost.

Pumps and Impellers for Leachate Extraction and Leachate Pumping

Popular pump types used for leachate extraction and pumping systems is the submersible centrifugal (vortex) type pump, and in particular in the UK the FLYGHT pumps model range.